-

Quick and Personal Service

- (256) 957-8106

- khatton@aspequipmentinc.com

- Mon - Fri 8AM - 5PM

Quick and Personal Service

Quick and Personal Service

ASP Construction, Inc. was started in 2017 by Dan Elkins in Alabama, after a career as a project manager for other successful general contractors around the country. As of this writing (2023), Dan’s company has grown to gross sales of nine million dollars per year. ASP focuses on additions, maintenance, concrete and steel work for plants and for larger GCs. Dan focuses on ASP, and he and Amanda attend a lot of little league baseball games.

Ken Hatton served as a valued subcontractor for ASP Construction from the start, fulfilling its loading dock equipment and overhead door

needs. In 2021, he was hired as a project manager, and in 2023, began operating ASP Equipment, Inc., Division of ASP Construction, Inc.. Ken has a long tenure in the loading dock equipment and overhead door industries, starting as a salesman in Louisville, Kentucky in 1986.

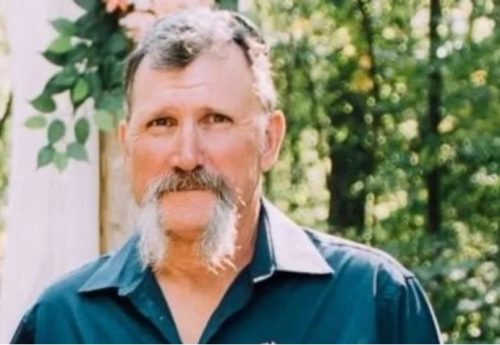

Since then, he has supplied the facility equipment for manufacturing plants, warehouses and distribution centers, whether the customer needed one dock or one hundred. (See photo attached of Ken and wife, Kay).

Hobby, you say? Ken is also a lifelong barbershop quartet lead singer, having traveled the country on weekends with his quartet, Bluegrass Student Union, for many years. Check them out on YouTube or, if you need a song sung, just ask him. The quartet earned status as an International Champion in competition, and Ken approaches the loading dock and door business with that same passion and expertise.

Since 2023, ASP Equipment, Inc. is a Facility Equipment distributor. We buy from the manufacturer, and sell to the end user (or to the general

contractor). We offer quality equipment, reasonably priced and properly applied. We respond the same day or the next day to your calls for

help, and we run to the phone to deliver bad news (It’s always better for everybody). We aren’t afraid to make promises, and we’ll do our best

to keep ’em. We cover Alabama from Montgomery, north to Tennessee, and we’ll respond to calls over the border in TN, MS and GA. We install,

maintain and repair anything we sell, and we’ll service any competitive brand as well. We warrant our new installations against defects in workmanship for a year, and our factories offer limited parts and labor warranties against defects in workmanship for up to twenty years.

When it comes to Planned Maintenance, we take a different approach. We bring a copy of the owner manual, and we read the PM instructions

(Imagine that!). We check the tightness of every fastener with a wrench (torque wrench when specified), and we carry all of the specified lubricants on the service truck. We hit all the lubrication points, and adjust the adjustment points listed in the manual. Then, we inspect, and write a thorough report, recording any minor repairs made, and any major repairs needed. That report gets condensed into an EXCEL file, which is sent to you a few days after completion of a PM visit. By the way, that EXCEL file includes the model and serial number, so that when you

call for help, we can often arrive with the part(s) needed for that specific piece of equipment. We expect our two man crew to spend a half

hour to PM each piece of equipment, because that’s how long it takes to do the work listed in the owner manual.